Fire Group 1-S products refer to building materials and products that have the highest level of fire resistance, according to the New Zealand Building Code (NZBC). These products can be used in high-risk areas such as commercial buildings, hospitals, and schools, to ensure that the building is adequately protected from fire.

The NZBC provides specific requirements for each type of building material and product, which must be met to comply with the building code.

Examples of Fire Group 1-S products that comply with the NZBC typically include non-combustible products such as fibrous cement.

It is important to note that the specific requirements for Fire Group 1-S products may vary depending on the building's intended use and location.

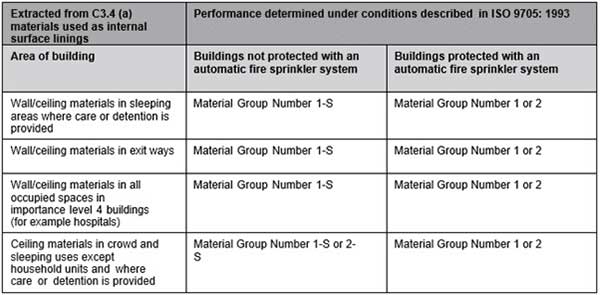

Clauses C1-C6 and A3 Building importance levels are used to determine Fire Group number. See extract from C3 - Fire affecting areas beyond the fire source below.

If an ‘S’ is appended to the Material Group Number, the material is required to meet smoke production criteria. The limit for maximum smoke production is 5.0 m²/s if the ISO 9705 test is used, or 250 m²/kg if the ISO 5660 test is used.

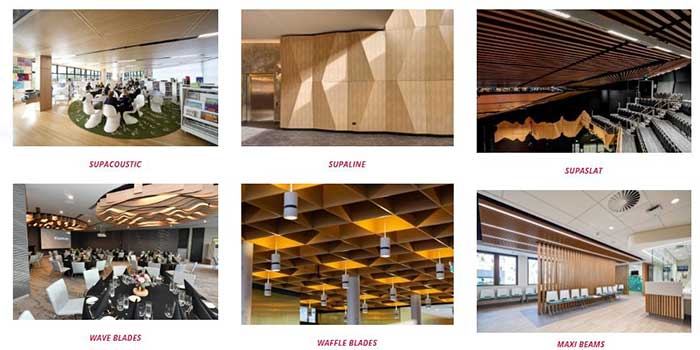

SUPAWOOD 1-S products

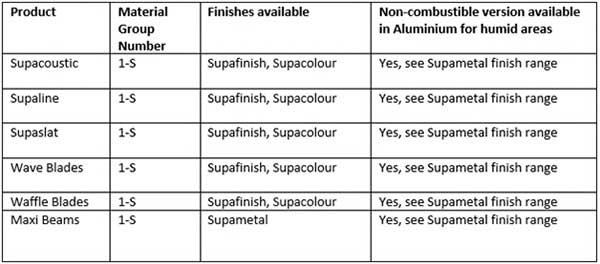

SUPAWOOD can supply panels, slats, beams, and blades to either a 1S or 2S Material Group Number. These have been certified with NZBC compliant test ISO 5660 or ISO 9705.

Since so many combinations of products are available, we have listed below the combinations that are certified for Material Group Number 1-S.

What is important to note here is that all these products achieve the Material Group Number without the use of intumescent paint. Instead, a fire-retarded or non-combustible substrate is used to achieve the needed Material Group Number. Intumescent paint is not recommended due to the many risks and problems it causes.

Conclusion

SUPAWOOD will only use fire tests and assessments from NATA or IANZ-accredited laboratories. We believe that only these fire engineers have experience in real-life testing situations, using peer-reviewed test methodologies and are ISO 17025 certified.

SUPAWOOD architectural lining systems fully comply with the relevant NCC/BCA standards in all respects: Reaction to Fire, Non-Combustibility, Seismic, Acoustic, and Sustainability. We are known for this and for providing clear and concise information to design and building professionals.

SUPAWOOD's approach

SUPAWOOD is the ‘compliance company’. Whether it be product compliance for acoustic, fire, seismic, or sustainability requirements, SUPAWOOD architectural lining systems are guaranteed to meet the needs of the appropriate building regulations.

SUPAWOOD products are extensively tested within the company’s testing facilities and with independent Certified Engineers, supported by test results and compliance certificates that can be relied upon even if required to be tested in court.

Proof of this is seen in our fire certificates, which are published in detail on our website. Nothing is concealed.

Please contact us if you would like more information or a free consultation on NZBC fire requirements for linings, or would like us to help you with a current project.