KOMBI access stairs, platforms and crossover systems were installed at Mars Wrigley’s Ballarat production facility to enable access to the rooftop HVAC plant.

Challenge

Access to the rooftop HVAC plant was hindered by large pipes, making maintenance extremely difficult for personnel. A sloping roof pitch added to the complexity of the project as did the tight clearances around, over and under the pipework.

Solution

Given the restricted access around the existing HVAC systems, the installer, PJM Engineering got in touch with the SAYFA design and engineering teams. Having never used KOMBI before, the installer was unfamiliar with the system. After assessing the project, the SAYFA team suggested KOMBI as an ideal solution.

“The modularity of KOMBI meant choosing this system for the project was actually a no-brainer,” commented Jeremy Parker, SAYFA corporate business manager, who took on the project management.

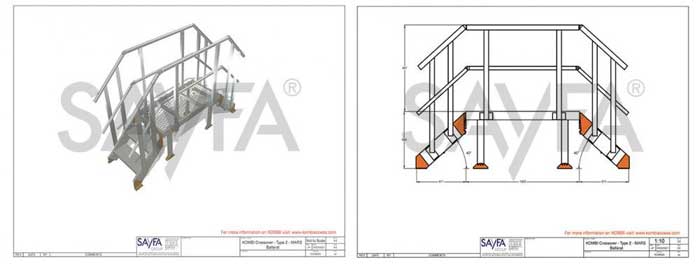

“When providing the client with a solution, it can be difficult for them to visualise exactly how it will satisfy their needs. With the use of the KOMBI Builda, we designed some initial concepts of the stair, platform and crossover systems. The KOMBI Builda outputs 3D models as well as various line drawings, which make the project come alive in the client’s eyes.”

Examples of the drawings produced at the conceptual stage by the KOMBI BUILDA.

Once these concepts were presented to the client and approval given, the SAYFA design team produced fully detailed and engineered design drawings specifically to accommodate the existing pipework and the degree of roof incline.

Fabrication began on three KOMBI crossovers and an access platform and the components were delivered to site. PJM’s personnel easily carried out the installation without any trouble.

“Site measurements had been taken prior to manufacture but there are often miscalculations, particularly when dealing with intricate pipeline networks. With KOMBI, on-site modifications can be easily made using the patented KOMBI T-Bolt. This was definitely a comforting factor for the installer,” Parker noted.

“An additional benefit is that the installation of KOMBI stairs and platforms requires no specialist tools or on-site welding, which makes the job even easier,” he added.

Why should you choose KOMBI crossovers and access platform systems?

HVAC systems in buildings can be difficult to access for maintenance teams, with the complex network of equipment, cables and piping making it difficult to navigate. Installing access stairs, platforms and crossovers into the existing HVAC set-up is a challenging process, requiring exact measurements to manufacture the systems.

If you are working with conventional fully welded systems, any error in measurements provided for manufacture can cause problems during installation, which can be expensive to fix and will lead to delays.

But when you choose the adjustable KOMBI stair and platform systems, any modification required during installation can be carried out onsite without needing a total rework.

Thanks to the patented KOMBI T-Bolt, there’s no need for onsite welding and fabrication. KOMBI access systems can be easily adjusted to accommodate unexpected site conditions such as uneven surfaces. The modular design of KOMBI systems allows flexibility, eliminating any complexity during installation.

The lightweight aluminium construction of KOMBI stair and platform systems offers multiple advantages over steel, a material that has traditionally been used in industrial applications. Read Aluminium vs Steel – Which Should You Choose? to know why you should ideally select aluminium for your access systems.

Proudly Australian owned and manufactured, KOMBI modular aluminium stairs and platforms offer the perfect solution for projects where lightweight, easy to install systems are required.