KOMBI modular systems met the brief and compliance requirements for a safe access and platform solution at the Suntop Solar Farm near Wellington, NSW.

Project requirements

The Suntop Solar Farm project will generate approximately 396GW of energy throughout the year, sufficient to meet the needs of over 65,000 homes.

Fitted with innovative single-axis tracking, the panels can follow the sun’s movement east to west each day. The solar farm will also provide a valuable boost to the local economy, with up to 400 workers required to maintain its operation during peak activity.

The raised delivery stations within the solar farm had no access or working platforms/surfaces to allow personnel to conduct maintenance operations. This was impairing the company’s ability to provide a safe and user-friendly working environment, a requirement of high importance to any employer.

The facility needed the provision of a platform system that could be easily unloaded, ideally without the use of cranes or heavy lifting equipment, and one which enabled installation by hand. As with most remote locations, specialist trades, tools and equipment can often be difficult and expensive to bring to site.

Additionally, all systems had to be compliant and engineered to meet stringent Australian Standard criteria.

Solution

Having previously worked together with SAYFA on the Melbourne Metro Tunnel project, the installer, Bouygues Construction Australia was confident that we could offer a practical solution for their client, Suntop Solar Farm.

Conceptual platform designs were originally provided to Bouygues using our KOMBI BUILDA configurator. This online program allows real time creation and produces drawings, parts lists, indicative pricing and 3D designs, which let the client visualise the systems being installed.

As part of the KOMBI BUILDA’s parameters, all designs that are created from the configurator are compliant to Australian and New Zealand Standards AS 1657 and AS/NZS 1170.

If further engineering is required to cater for requirements such as specific weight or wind loads, SAYFA’s Engineering Team can assist with incorporating these custom specifications into the designs.

Once feedback and comments were received, SAYFA’s Design Team produced detailed design drawings, which were signed off by Bouygues before commencing manufacture.

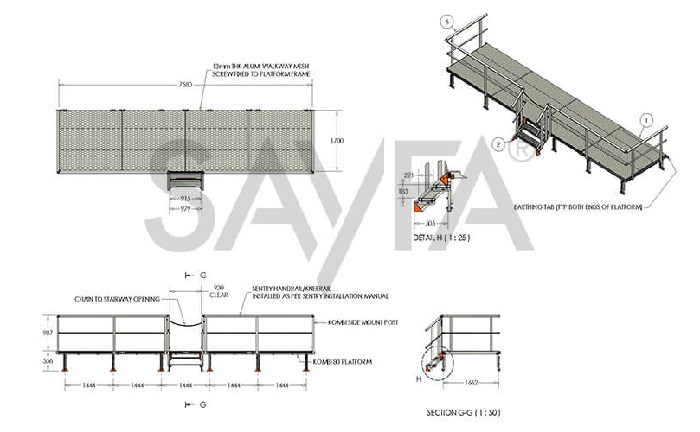

Final Design - detailed drawings provided by SAYFA’s in-house Design Team for manufacture.

The KOMBI platforms were pre-assembled by SAYFA’s Production Team at our Boronia facility and then delivered to site in modules. This ensured a quicker and easier install for the project. However, KOMBI components can also be delivered as flat packs to reduce transportation costs or if the delivery location has constraints such as lift access only or limited available space.

As the installation was taking place in country NSW, consideration had to be made to enable minimal site preparation for the platforms.

“The KOMBI platforms feature proprietary adjustable legs so the Bouygues Team could modify the height and angle on-site to suit varying ground level conditions. It was then very quickly bolted together, saving both time and money,” Jeremy Parker, SAYFA corporate business manager stated.

“This resulted in a fast, effective and compliant install, which in turn made for a very happy KOMBI client.”

Advantages of KOMBI Aluminium Stair and Platform Systems

Manufactured in Australia, KOMBI systems are constructed of lightweight aluminium and designed to Australian and New Zealand Standards AS 1657 and AS/NZS 1170.

KOMBI Modular Aluminium Stairs and Platforms are totally flexible, and their design is only limited to your imagination.

Last minute changes to site conditions or structures are no problem due to the innovative KOMBI T-Bolt, which allows height and angle adjustments to suit any variation.

Why aluminium?

The construction of KOMBI in lightweight aluminium enables personnel to easily carry and handle the components within maximum handling guidelines.

Steel access systems have been considered the go-to material of construction for many years. Whilst there can be minor cost savings when choosing to manufacture systems out of steel, aluminium provides many advantages. Read our detailed comparison of Aluminium vs Steel to learn why we choose aluminium for our systems.

Proudly Australian owned and manufactured, KOMBI modular aluminium stairs and platforms provide the answer when lightweight, easy to install systems are required.