An updated cradle-to-gate analysis report completed by climate change consultancy Verco, has shown that Accoya’s carbon footprint significantly outperforms most other building materials, including a wide range of sustainably-sourced hardwoods.

The report noted that following an exhaustive cradle-to-gate analysis undertaken in 2009, Accoya’s manufacturer, Accsys Technologies, has made significant progress in “updating a range of production parameters in a continuing improvement of environmental and overall performance.”

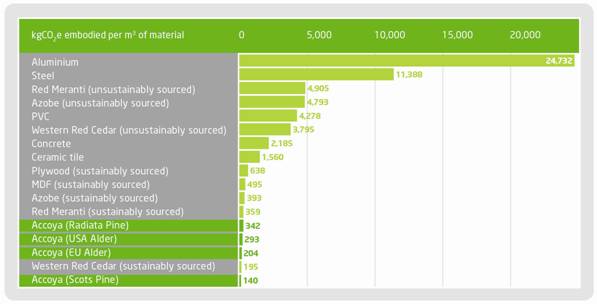

The current environmental impact of Accoya’s production process was set against that of other popular construction materials such as concrete, PVC, steel, aluminium, MDF and plywood as well as a range of sustainably-sourced hardwoods such as azobe and red meranti. Results showed that Accoya’s carbon footprint outperformed these materials based on wood-sourcing options currently available.

Greenhouse gas emissions (cradle to gate) in kg CO2 eq per cubic meter in various material alternatives

Greenhouse gas emissions (cradle to gate) in kg CO2 eq per cubic meter in various material alternatives

Verco also analysed the potential full life span impact of Accoya on the environment in terms of greenhouse gas emissions. The report revealed that Accoya’s high strength-to-weight ratio, its low maintenance requirements, combined with its increased carbon sink potential through increased durability and good recyclability during end-of-life, could provide even additional environmental benefits.

Subsequent carbon footprint analysis by the Delft University of Technology on a cradle to grave basis took these life cycle aspects into account and revealed that Accoya window frames are CO2 negative over the full life cycle of the product, mainly thanks to the limited emissions during production and benefits gained from carbon sequestration during the life span of the durable acetylated wood.

Greenhouse gas emissions (cradle to grave) in kg CO2 eq per window frame in various material alternatives

Greenhouse gas emissions (cradle to grave) in kg CO2 eq per window frame in various material alternatives

Welcoming the recent carbon footprint analysis, Bryan Crennell director of sales and marketing from Accsys Technologies said: “During the last three years we have worked in partnership with our suppliers to improve production techniques and we are delighted that this effort has been verified.”

“We are also pleased that the acetylation process involved in creating Accoya, has been recognised by the report as an environmentally friendly method of wood modification. The acetylation process modifies the wood at a molecular level, which not only significantly improves the stability and durability of the product but releases less carbon dioxide emissions than alternative methods.”

“The demand for tropical hardwood in recent years has put significant pressure on rainforests leading to deforestation. These results show that Accoya offers a viable solution and alternative to tropical hardwoods by enabling abundantly available, sustainably sourced temperate wood species to deliver on performance while reducing impact on the environment,” said Mr Crennell.