As part of the building envelope, the roof protects a building from the natural elements. Some roofing products even go all out by providing a complete solution for roof, insulation and ceiling. Steel roofing plays a part in this all-in-one solution, while, at the same time, allows flexibility for interesting shaped roofs.

Here are three of the latest offerings in the steel roofing market which exhibit the current state of play, including the latest technology and product developments.

Fielders

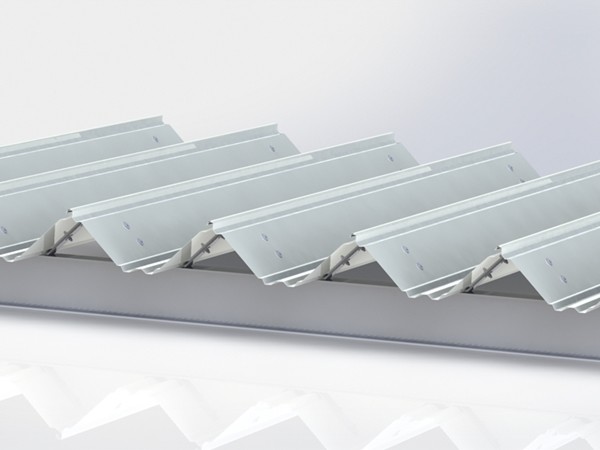

One of the key product offerings from Fielders is the Aramax FreeSpan profile, which was formed and created by Wade Blazely around 22 years ago.

With an innovative V shape and a unique profile, Aramax is a cold formed steel structural product. It is manufactured in standard 800mm cover width, but varying cover widths can create ‘fan-shaped’ and other odd geometrical roof shapes, such as the White Bay passenger terminal. It is waterproof and can accommodate cantilever overhangs of up to six metres, depending on internal span geometry.

So why should designers chose Aramax for their projects? A very unique aesthetic look of the profile can provide a modern, cutting edge to any building.

Fielders general manager of sales, marketing and engineering Matt Lloyde says, “More and more designers have been opting for this profile not only because of its excellent spanning capabilities and aesthetic, but its ability to save costs, which is vital in an unpredictable market.”

Additionally, with being produced on a mobile roll-former, Aramax can be rolled onsite anywhere, reducing construction time and improving project efficiencies.

Aramax caters to large spans of up to 20 metres without the need for purlins or girts, eliminating cost and complexity of building other structural elements by 30 per cent.

So where next for Aramax? Lloyde says future developments include the integration of a thin film of photovoltaic technology to capture solar energy, mainly on underutilised areas of the roof so as not to impact on design.

Working with Johnson Pilton Walker, Fielders provided Aramax to Sydney’s new $57 million cruise terminal facility at White Bay.

Aramax FreeSpan 1.2mm perforated ceiling, and a 1.2mm aluminium roofscape in Mill finish made up the 7152sqm of roofing used on the new facility.

The steel roof of the new cruise terminal facility at White Bay.

The steel roof of the new cruise terminal facility at White Bay.

It was selected as it allowed the complex curved wave shape of the roof design, along with its long spanning capabilities, and resistance to corrosion due to the close vicinity of the ocean.

The terminal was recently awarded the ‘Transport Winner’ at the 2013 World Architecture Festival.

Bondor

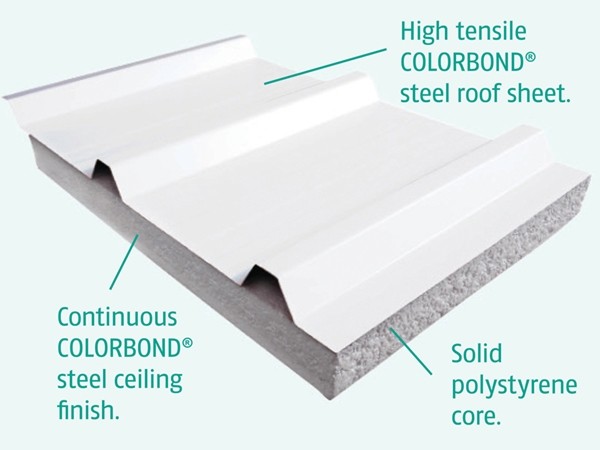

Bondor offers SolarSpan - a three-layered system with insulation wrapped in Colorbond steel.

SolarSpan is an insulated composite roofing product which offers long-spans, low pitch and high thermal efficiency. As an all-in-one insulated roofing solution, it offers a ceiling, insulation and roof sheet in one product.

If features a Colorbond steel exterior, an expanded polystyrene core with fire-retardant, and a pre-painted Colorbond steel underside.

It is faster to install than conventional roofing, while the need for traditional trusses, mesh, sarking, insulation and plasterboard are all eliminated.

Bondor general manager Geoff Marsdon says, “This saves a significant amount of building material, it also means the whole system is installed in half the time of a traditional roof.”

Key advantages include blocking heat, reduction in build time and cost, and is low maintenance while providing comfort all year round.

SolarSpan is specified because of its greater spanning capabilities over traditional roofing, which allows designers to create large, dramatic open spaces with plenty of airflow and light, Marsdon says.

Additionally, the insulating core is bonded to the steel facings, so it does not crumble, sag or deteriorate over time, giving consistent insulating quality over the building’s lifetime.

As one of Bondor’s key products, SolarSpan has been incorporated into the InsulLiving home, which has proven energy-efficiency ratings.

The InsulLiving house at Wilton, NSW.

The InsulLiving house at Wilton, NSW.

InsulLiving was Bondor’s step towards a zero energy housing and combines the InsulWall and SolarSpan products to create a complete thermal envelope, which currently exceeds the thermal efficiency requirements set out by the Building Code of Australia.

Several InsulLiving homes are now in Australia, with the latest being the display home in Wilton, NSW.

Built by Hampshire homes, and using Bondor’s SolarSpan as the roofing, the display home is an eight-star energy-rated home.

Marsdon says the InsulLiving system has proven successful across Australia and has significant potential for the New South Wales residential building sector, for architects and builders, through to homeowners.

The original prototype house built in Burpengary, Queensland earned an ‘as designed’ energy rating of eight stars, which then achieved a ‘real life’ energy rating of 9.5 stars after a year of independent study by Queensland University of Technology.

Bluescope

Colorbond - what would steel roofing in Australia be without it? Many other steel roofing products use Colorbond as the basis, as already mentioned with Bondor’s SolarSpan.

Bluescope have just recently updated Colorbond with several major changes including adding six new colours to the range.

The biggest change is probably the new Activate technology - a metal coating found underneath the painted surface - which has made the roofing more corrosion-resistant.

Additionally, new paint technology has increased the colour durability and gloss retention of all colours when compared to previous-generation Colorbond steel.

The new generation of Colorbond is better suited than ever to Australian conditions with BlueScope marketing manager - building markets Ashley Whitter says, “Colorbond steel is developed for, and therefore more resilient to, the intense sunlight and temperatures typical of Australian environments.”

Additionally, Bluescope’s efforts to reduce Colorbond’s environmental footprint have been rewarded with positive results.

An independent comparative environmental life cycle assessment (LCA) has shown the latest version of Colorbond outperforms its predecessor consistently in 18 categories, which measure impacts on air, water, land and human health.

According to the LCA, this reduced impact is the result of the new metal coating formulation.

As the new Colorbond is so new, there are currently no projects utilising the new generation.

However, a recent project using the previous generation of Colorbond, which still has similar properties of the new generation, is Trades North, West Coast Institute of Training.

Trades North. Image: Daniel Eaton

Trades North. Image: Daniel Eaton

The design of the building was to respond to the harsh climate of Western Australia, particularly as the long elevation directly faces the western sun.

Designed by JCY Architects and Urban Designers, Trades North features split, curved roofs, which were only possibly using steel.

Colorbond was used on the roofing, walling, flashings and trim. It provided flexibility in creating the curves and allowed them to be made in a single piece. This meant less maintenance and leakage of the roof system.

Ultimately, Colorbond was the most cost-effective solution for what JCY wanted to achieve at Trades North, as well as offering the flexibility they were looking for.