At the close of 2015, The Sustainable Buildings Research Centre (SBRC) at NSW’s University of Wollongong could become Australia’s first building to achieve a Living Building Challenge (LBC) certification, arguably the most advanced measure of sustainability in the built environment possible.

Designed by Cox Architecture, the SBRC features a myriad of sustainable building materials and design elements that were chosen to meet the imperatives of the LBC and establish the centre as an integrated research site for the performance of sustainable building technologies in Australia.

One building technology recruited to meet the LBC imperatives, and now being closely monitored by the university, is the building’s geo source heat exchanger that feeds ground tempered water into the building’s in-slab hydronic heating system.

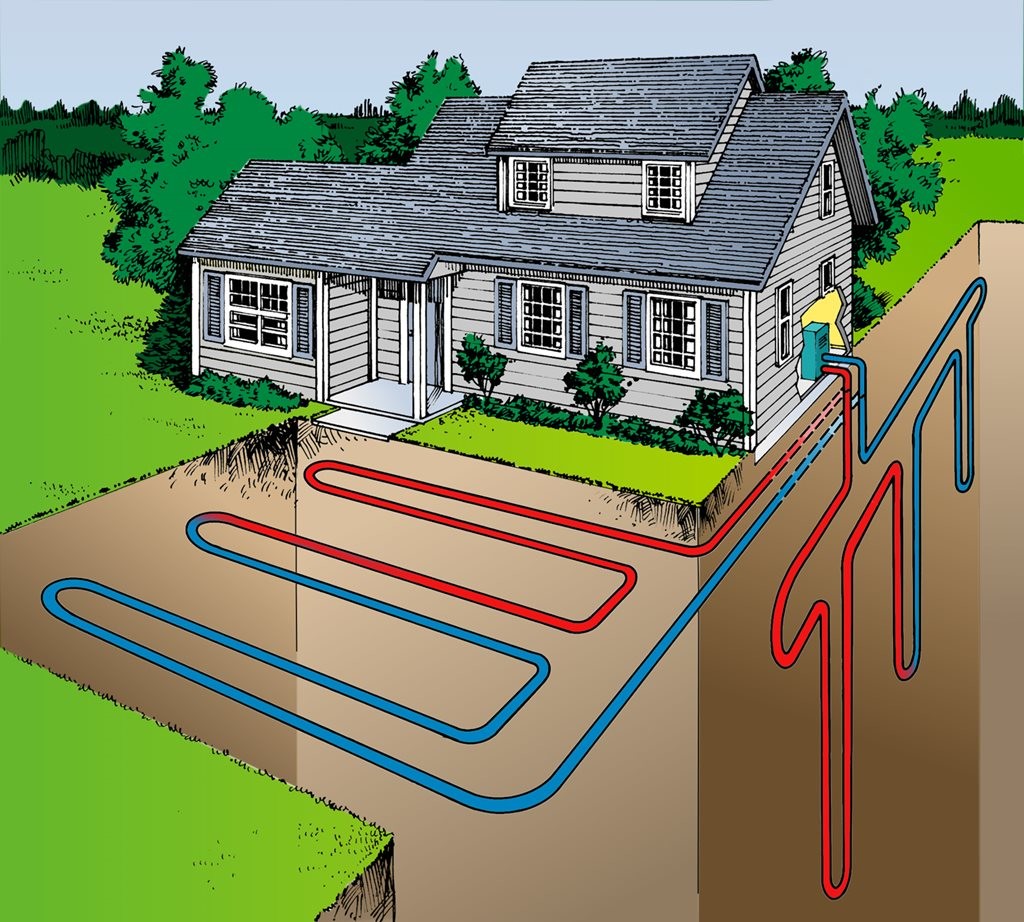

Geo-exchange systems basically consist of a pipe-loop that is placed underground and pumped with water in order to extract heat from the earth’s thermal mass. The water runs through a closed circuit into the thermal mass of the earth, changing its temperature before it is pumped back to the building to use in heating systems.

The loops can be laid under the earth in a horizontal setup—usually 1.5 metres deep and up to 150 metres long, or a vertical loop where a drilling rig is used to bore holes for pipes to be fed in to.

A typical horizontal and vertical geo exchange format. Image: Geothermal Innovation.

A typical horizontal and vertical geo exchange format. Image: Geothermal Innovation.

Keeping with the building’s role as a prototype for new building technologies, Cox chose to use both horizontal and vertical pipe formats for the SBRC so that their efficiencies can be monitored and tested.

“As part of the centre’s research, the university wanted to understand the efficiencies of the two systems,” said project architect Michael Bradburn of Cox Architecture.

“So two loop systems were chosen, one horizontal and one with vertical bores, but both come into a manifold which mixes them differently and monitors their temperatures and efficiencies.”

Once the water is pumped through the ground source heat exchanger and tempered to the desired temperature, it is pumped through the building’s in-slab hydronic floor system.

Bradburn says the shotcrete-like insulation is a questionable but necessary choice for a front of house ceiling.

Bradburn says the shotcrete-like insulation is a questionable but necessary choice for a front of house ceiling.

The hydronic flooring system at the SBRC is in itself an architectural feat, and Bradburn admits that it meant a little bit of extra work on behalf of the builders to get the system to work in the building’s post-tensioned second storey slab.

“Where typically you’d pour the slab, cover it with an insulating layer and then cast the hydronic pipes in a topping screed, the pipes at the SRBC are actually cast into the structural post-tension slab,” he said.

“The reason we put it in the structural slab was so that the slab’s thermal mass in its entirety could be activated, but it made for a more difficult job for our builder.”

“It ended up being a very complicated slab to construct with all the reinforcing post-tension cables plus all the hydronic pipe work.”

Bradburn said this system meant that the slab could be turned on and begin storing heat in the early morning, so that when people come into the building at opening times there would already be heat stored in the mass.

The SBRC is powered by 100% renewable energy from 160kW PV array, and features a 5kW building integrated photovoltaic thermal system, a Micro-Grid Distribution System, a rainwater capture, storage and treatment system and a black water treatment plant.

The SBRC is powered by 100% renewable energy from 160kW PV array, and features a 5kW building integrated photovoltaic thermal system, a Micro-Grid Distribution System, a rainwater capture, storage and treatment system and a black water treatment plant.

But what about the bottom of the slab? how do you prevent heat loss?

Bradburn said that insulating the underside of the post-tension slab was one of the more difficult tasks, on the account that the insulating product had to meet a range of LBC requirements while keeping with the building’s “engineering” aesthetic.

“Because of the engineering nature of the building, the clients were very keen to expose all the services as part of the education aspect of the building,” said Bradburn.

“Finding an insulation product for the underside of the slab proved very difficult as it needed to achieve high sound absorption performance (reverberation control), meet all the fire indices of the BCA, meet all the “red list” chemical and sourcing criteria of the LBC, and still give us the thermal performance we needed.

“We ended up with a paper pulp insulation that looks a bit like shotcrete and garners a lot of questions from visitors considering it’s situated on the underside of the slab at the front of house.”

The SBRC is currently being considered for the NSW Architecture Awards – Educational Category.

Photography by John Gollings and Richard Glover.