The concrete boom from the previous century has relied on available workforce, as formwork building is the most time-consuming phase in in-situ casting of concrete structures.

The ever-continuing urbanisation and economic development have pushed the disadvantages of in-situ casting into the open due to challenges such as lack of time and space; pollution and waste generation; and costs to society and the environment and immediate or indirect health risks.

The challenges and problems of construction, on the other hand, have called for developing efficient or modular methods. The resulting development could be considered to be either prefabrication of structures, or mechanical or automation-aided concrete casting.

Prefabrication of reinforced and (steel-) composite concrete structures

Precast concrete (PC) structures are manufactured centrally and then sent directly or through depots to the jobsite located at a moderate distance by trucks (between cities or provinces typically). Industrialised casting makes possible a regulated indoor work environment, serialised production with some freedom to structural shape, and efficient quality control, just to mention the most obvious. Prefabrication of composite sections using steel as partly structural, partly concrete casting mould also enabled fast construction. Moreover, BIM, FEM and academic engineering advances have made many types of composite structures available, resulting in a variety of efficient slab construction methods, combining wooden or steel beams or sheets with concrete. (Figure 3)

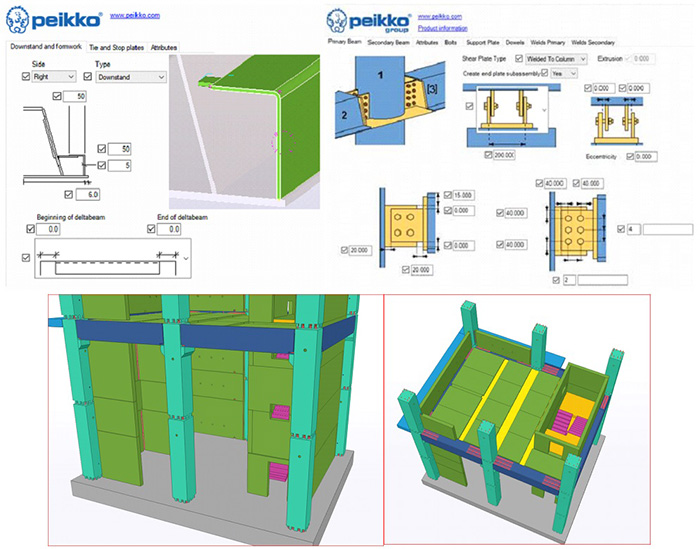

Figure 1: Precast composite slimfloor slab using precast hollow-core (HCS) planks; note large perimeter formworks to create cantilever slabs, or shapes in slab along façade – last picture is timber-concrete slab with shear- plate composite connectors

Figure 2: Precast column lifting and connection with shoe is a popular precast connection tightening with concrete anchor bolts

Figure 3: Modular modelling for standardised steel-concrete composite structure production in BIM software

Precast needs early planning and dedication to the design of specialised frame elements for a variety of actions. A factory, on the other hand, needs planning and acquisition of complex and advanced inventory for forming, reinforcing, tilting, moving etc.:

- Forms, formwork systems, perhaps complicated formwork elements, or even tilting tables

- Reinforcement storing, cutting, bending and cage assembly areas

- Concrete pouring, vibration (possibly a table) and curing equipment

- Overhead beam crane or other possible hoisting equipment for in-factory or outward hoisting

Figure 4:

Top: Precast slab factory typical equipment line-up

Bottom: Massive/monolithic PC – note protruding reinforcement for ‘wet’ (casted, stiff joint) connecting on site

L to R, top-down: lintels, wall, façade and balcony, staircase, half-cast beams, etc.

Precast can become massive for industrial or extremely large constructions or when spans get very long. The element thickness or height can be limited to lighten the element. Special cases of lifting can utilise multiple smaller vehicles and a combination of lifting points and equipment added to the hook.

Figure 5:

Right: Long span or massive precast elements can be an alternative when lifting

Left: PC beams constructed on wide transfer beam and two columns

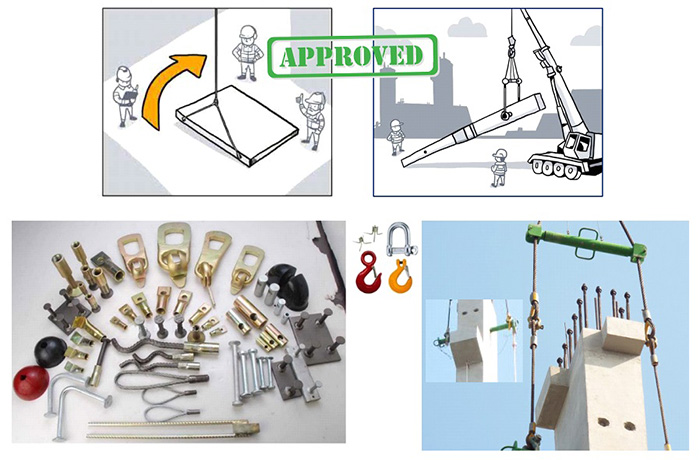

Figure 6: Variety of lifting insert types for countless variety of PC shapes – on right, turning a large panel with 2 cranes

Figure 7: PC concrete lifting equipment and conditions

Precast can be challenging with varying design, block size and building conditions. With mature and sophisticated product family and combinations of connections and inserts, project outcomes can be achieved.

Referred material

Literature and handbooks:

Diaphragms globaljournals.org/:Investigation_into_the_Floor_Diaphragms_Flexibility_in.pdf

fib Bulletin 43 Structural connections for precast concrete buildings

fib Bulletin 74 Planning and design handbook on precast building structures

fib Bulletin 73 Tall buildings

Cuerrier-Auclair, Design guide for timber-concrete Composite floors in Canada, 2020, FPInnovations

Construction technics and solutions, referred above:

Overhead crane example, https://overheadcranesuppliers.com/overhead-beam-crane/

Green slimfloor https://www.peikko.com/products/deltabeam-slim-floor-structures/deltabeam-green/

Making bolted connections seismic, https://www.peikko.com/products/connections-for-seismic-design/technical-information/