In the world of sustainable materials, bamboo holds a steadily growing and special place. This article will examine the emergence of engineered bamboo, consider bamboo’s role as a high-end green building material and look at some examples of new sustainable ‘green building’ projects.

Bamboo: Beyond the Tiki bar aesthetic

Bamboo can conjure images of tropical landscapes, Tiki bars, and decorative elements. This charming, textural element is not the only feature of bamboo worth noting. The engineering of bamboo has provided a new resource that can help offset Australia’s timber shortage and ultimately become a partner to the timber and construction industries.

The drive to reduce carbon emissions by the construction industry has meant it has started to look at new ways to make their practices greener. The overall goal is to reduce the amount of ‘embodied carbon’ within construction. Embodied carbon refers to the total carbon emissions released during construction, renovation, and demolition. As such we have seen the proliferation of a number of so-called ‘green buildings’ being built across the world, including Australia.

One of the ways to reduce emissions is to increase the use of lumber in construction. By reducing the use of materials such as concrete and then including greener materials such as timber, the construction industry can start to achieve their goals. However, questions have been raised about the true sustainability of this practice.

The main concern with timber demand is that any increase will put pressure on timber stocks that are already strained. We have recently experienced supply issues due to the bushfires of 2019-2020 and COVID-19. The Russian invasion of Ukraine has also had a heavy impact on timber supply out of Ukraine, Russia and Belarus. Trade sanctions on Russia and Belarus have only deepened these timber shortages.

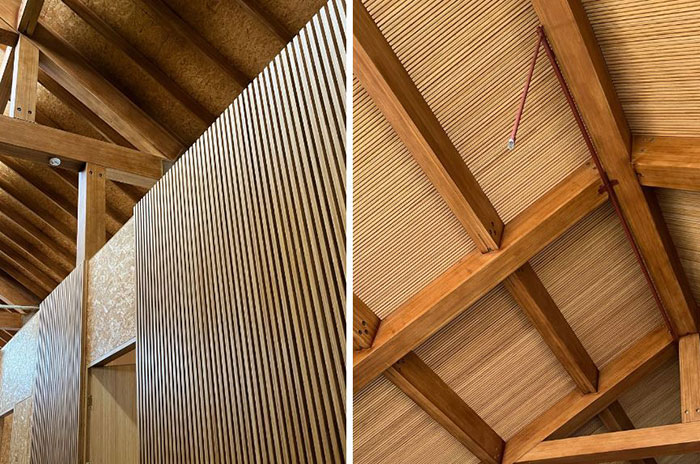

One option to help mitigate these shortages is to use engineered bamboo. In this process, bamboo fibres are bonded together under high pressure to produce materials for construction. Engineered bamboo offers enhanced strength, durability, and dimensional stability, making it an excellent substitute for traditional timber. In fact, it can be stronger than many hardwood species, making it suitable for demanding structural applications.

Engineered bamboo: Redefining strength and durability

Dimensional stability is another critical attribute of engineered bamboo. Traditional bamboo materials – similar to any natural material – are prone to expansion and contraction due to changes in moisture and temperature. Through the manufacturing process of engineered bamboo, fibres are aligned and compressed significantly, reducing the material’s susceptibility to these stresses. This dimensional stability ensures that engineered bamboo maintains its structural integrity over time, even under challenging environmental conditions.

The timber equivalent to engineered bamboo is CLT (Cross Laminated Timber). CLT falls under the mass timber umbrella as a product engineered for strength comparable with concrete. It is these technologies that will be employed by the construction industry as they construct greener buildings. Engineered bamboo, however, offers other benefits to CLT as it builds upon the inherent sustainability as a rapidly renewable resource unlike timber.

When it comes to bamboo, nothing goes to waste. Engineered bamboo utilises bamboo stems that have reached maturity and the appropriate level of strength of density – this takes approximately 5-7 years. Whereas the softwood timber used to make CLT takes upwards of 30+ years to reach a level of maturity suitable for production. Engineered bamboo is a strong contender to CLT, making it a good alternate choice while not relying on a depleting forest industry.

How engineered bamboo can help solve skyrocketing timber wastage

A point must be made regarding waste when it comes to timber harvesting. A 2019 report released by the Sustainable Built Environment Research Centre of Australia provided statistics on timber waste from around the world and found that in 2016-2017 Australia generated more than 2 million tonnes of timber waste and 25.8% of this waste was attributed to the construction and demolition sector.

Another more recent study conducted by Dr Jen Sanger for the Trees Project found that when harvesting timber in NSW, approximately 60% of the total biomass is left on site. Half of this is woody debris that is left on site while the rest is burnt. In contrast, bamboo harvests the mature culm (stem) leaving behind the root, which remains in place in order to re-grow another stem for a future harvest.

We can further reduce the need for timber and put less pressure on the already limited supply by utilising engineered bamboo for elements such as beams, posts, trusses, flooring, wall cladding and even roofing material.

Australia’s construction landscape goes green: The rise of sustainable buildings

Some examples of new local hybrid timber buildings include the world’s tallest hybrid timber tower being built by tech giant Atlassian in Sydney; the Boola Katitjin at Murdoch University in Western Australia; and T3 Collingwood – a 15-level hybrid timber office in Melbourne.

(L) Building 360 - Boola Katitjin, Murdoch University; Architects: Lyons and (R) Atlassian HQ in Sydney

These buildings will be setting a benchmark for sustainability. Atlassian’s building has targeted a 50% reduction in embodied carbon (embodied carbon is the carbon dioxide emissions associated with materials and construction processes throughout the whole lifecycle of a building). This is a fantastic target; however, both Atlassian and the Boola Katitjin building have needed to resort to importing timber from Europe as softwood timber supplies needed for CLT are in short supply within Australia. If engineered bamboo had been incorporated into these designs, both projects would be making even further strides towards the sustainable future they envisaged.

Hybridity in urban streetscape - T3 Collingwood

The T3 Collingwood building will receive a $70 million investment from the Clean Energy Finance Corporation. The building hopes to lower embodied carbon by 34%. It is this sort of investment and commitment that we need for the bamboo industry. Bamboo provides a viable and sustainable alternative to Australia’s critically depleted timber stocks for the construction of green buildings. Bamboo’s rapid growth, renewability and versatility make it an attractive resource that deserves funding and support. By investing in the bamboo sector, governments can further reduce emissions, build new industries and protect local forests.