Concrete drainage channels often have to be replaced due to damage or wear caused by weather or exposure to chemicals being carried by the drainage system. Polypropylene drainage channels are increasingly being used to replace these damaged concrete channels.

There are several reasons why polypropylene channels should be favoured over concrete or polymer alternatives.

Polypropylene channels guarantee an optimal and aesthetically satisfying outcome in all projects that require an easy-to-install and durable solution.

Ease of installation and reduced installation costs

Polypropylene is a lightweight material that makes these channels easy to transport, handle and install onsite. Concrete channels, in comparison, are much heavier than polypropylene channels, significantly impacting labour and transport costs.

For example, based on the same performance parameters, a drainage channel made of polypropylene, class D400 with an internal section of 200x200mm has a weight of approximately 22kg, while a concrete channel can weigh up to 130kg. The heavier concrete channels will need equipment to handle them during transportation and installation, leading to higher costs.

Being considerably lighter, polypropylene channels can be installed directly by the workforce, and with ease.

Less internal roughness means higher water flow

When comparing polypropylene and concrete or concrete-polymer channels of the same size, polypropylene channels have been found to transport more water. This is because polypropylene channels have less internal roughness, which allows more water or liquids to be transported with the same internal cross-sectional area.

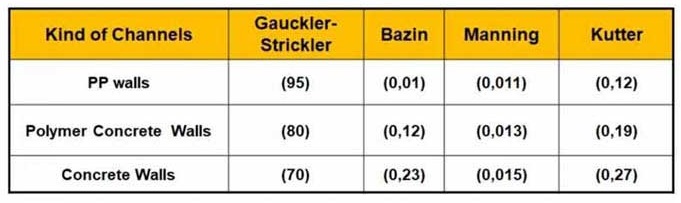

In hydraulics, coefficients associated with the internal roughness of the walls are used, with Gauckler-Strickler, Bazin, Manning or Kutter formulas being applied to estimate the velocity of water flowing in open channels. As stated in the table below, polypropylene performs significantly better than other materials from which drainage channels are commonly manufactured.

For example, taking the Gauckler-Strickler coefficient as a reference, polypropylene has an index of 95 compared to 70 for cement and 80 for concrete-polymer.

Resistance to chemicals

In their article on rainwater drainage channels in service stations and forecourts, SABdrain states that chemical resistance is an important factor to evaluate when considering the replacement of existing channels. Extending the useful life of the drainage system decreases the chances of an emergency intervention to replace or repair drainage channels that have been installed previously.

An example of this type of intervention was the installation of SABdrain channels in petrol stations in Jordan for three major fuel distribution players: JoPetrol, Total and Al Manaseer. The project involved about 2,000 metres of drainage and the proximity of Gersa’s stations next to Hadrian’s Arch, a historical and artistic beauty dating back to 130 AD, made the success of the project even more relevant and significant.

Initially, these petrol stations used concrete channels to optimise material costs. However, this solution soon led to a serious problem with the rapid deterioration of the channels. This led to the replacement of the concrete channels with SAB polypropylene channels.