Q: Explain the RMAX / BASF Partnership

A: BASF has fostered and supported the use of Neopor® an enhanced EPS product in Australia. RMAX have been an early and active adopter of this technology and are the first EPS manufacturer in Australia to do so. The inventiveness of BASF and the innovative application of technology by RMAX make for a strong partnership.

Q: Can you explain the Neopor® Technology?

A: Neopor® stands apart from traditional EPS because it contains tiny graphite particles that reflect radiant heat and give the material its silver-gray shine. These infrared absorbers and reflectors improve the thermal insulation property so that insulating panels made of Neopor® can be about 20 per cent thinner than panels made of traditional EPS.

Q: Why is efficient insulation so important today?

A: Poor insulation contributes to a wasteful use of energy in Australia. Modern building practices now require new construction methods to conform to six star energy ratings putting pressure on architects and builders to explore new, efficient materials that will assist achieve this.

Efficient insulation will keep a building cool in summer by reflecting heat and warm in winter by retaining heat. This not only makes the structure more comfortable all year but will save money on reduced heating and cooling costs

Q: How is RMAX ThermaSilver™ made?

A: BASF produce the raw Neopor® EPS material. It comprises small black beads that contain blowing agents and consequently can be expanded.

RMAX then take the black Neopor® beads and manufacture the silver-grey foam blocks of ThermaSilver™. These blocks are then cut into panels of specific thicknesses that deliver the required R-value for a building.

Q: Where can ThermaSilver™ be used?

A: ThermaSilver™ is suitable for a multitude of internal and external applications including exterior insulation and finishing systems (EIFS), ceiling insulation, exterior insulation, cavity insulation, which is the application used in the Flannery Centre, Insulating concrete forms (ICF’s), panel construction and floor insulation such as RMAX ThermaFlex™.

Small black beads of Neopor® are at the heart of ThermaSilver™ insulation efficiency providing superior thermal insulation.

Small black beads of Neopor® are at the heart of ThermaSilver™ insulation efficiency providing superior thermal insulation.

Q: What is Eco-Efficiency?

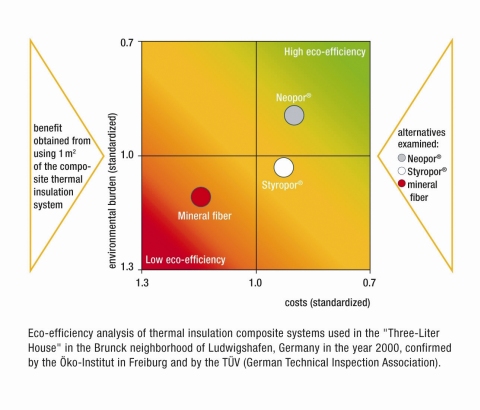

A: Eco- efficiency means giving equal weight to both costs and environmental impact. Material and energy consumption, costs and savings potential define a product’s eco-efficiency.

Products are plotted on a four quadrant system with costs on the horizontal axis and environmental effects on the vertical axis. If total costs are low, the product is situated in the right hand section. This measure includes all costs ranging from manufacture to end use.

The ideal position is to be in the top right hand quadrant as Neopor® is. Whilst EPS does not rate as well as Neopor®, it is still positioned on the positive side of the diagram, unlike mineral fibres.

Q: How energy efficient is ThermaSilver™?

A: Extremely energy efficient. The energy saved over the lifetime of a ThermaSilver™ panel in reduced energy demand more than compensates for the raw material used in its production.

Q: What are the main benefits of RMAX ThermaSilver™?

A: Better insulation for a given panel thickness. ThermaSilver™ can provide up to 20 per cent more insulation performance with the same board thickness when compared with conventional EPS of the same thickness.

Conversely, a thinner ThermaWallSilver™ board can be used to achieve the same R value of conventional EPS saving space, which is important in medium / high density construction.

The thinner ThermaSilver™ panel does not reduce insulation efficiency.

Q: What are the environmental benefits of ThermaSilver™?

A: There are many environmental benefits when specifying ThermaSilver™. The key benefits are:

• Provides a more effective insulation, reducing heating and cooling costs for the life of the building

• A thinner board uses fewer raw materials and with ThermaSilver™ comprising 97 per cent to 99 per cent air and only 1 per cent- 3 per cent material, this benefit is magnified

• ThermaSilver™ is 100 per cent recyclable

• Once installed, ThermaSilver™ does not deteriorate and will last the life of the structure

Moreover, environmentally friendly ThermaSilver ™ does not contain CFCs, HCFCs, HFC or other ozone depleting halogenated cell gases. Neopor® contains air as cell gas — this supports the preservation of the thermal insulation property of the insulation material made from Neopor®.

Q: What are the practical advantages of RMAX ThermaSilver™

• Greatly improved insulation effect

• Dimensionally stable, weather-resistant and ageing-resistant

• Non-glare work in direct sunlight due to reduction of light reflection

• Easy handling during processing due to weight advantage

• Easy to cut and install

• Proven processing method similar to conventional EPS

• Versatile application possibilities

• Proven performance in buildings in Europe

Q: What are the technical specifications?

A: ThermaSilver™ can be supplied in a variety of densities and sizes to suit particular insulation requirements. Density varies from 13.5 grams per

litre to 28 grams per litre. Sheet size maximum is 5.0 metres X 1.2 metres with thickness up to 0.6 metres.

Q: Does ThermaSilver™ have better thermal conductivity?

A: ThermaSilver™ improves insulation when compared to other materials. ThermaWallSilver™ with a build density of 15kg/m3, achieves a lower thermal conductivity of 0.032W/(m.K), measured at 10 degrees Celsius, which translates into a higher R value. In normal EPS with the same bulk density, the thermal conductivity is 0.038W / (m.K).

Q: Is ThermaSilver™ subject to Australian Standards?

A: Yes. RMAX manufacture ThermaSilver™ to ensure its physical characteristics meet the standards specified in AS 1366 Part 3 - 1992. As such, the properties of ThermaSilver™ required for a particular application are guaranteed. Where the densities exceed the AS1366 Part 3 - 1992 grade levels RMAX has measured the properties and provides specification sheets for these high density grades.

Q: Where has RMAX ThermaSilver™ and Neopor® been used?

A: The Flannery Centre Bathurst, NSW

Once completed, the Flannery Centre will be a world class example of sustainable building practices. It will be the home of education in sustainability in the region, educating and showcasing leading edge sustainable building solutions

The complete ThermaSilver ™ story can be found on www.rmax.com.au/ building products eps/thermasilver.

If your next project requires a unique insulation solution, contact RMAX on 1300 888 972 and talk to one of our specialists or visit our web site.

ZERO HEATING HOUSE

Passive House New York State

Neopor® is featured in the first certified Passive House in New York State. Designed by Dennis Wedlick Architect, LLC (DWA). This three-bedroom home achieved a 90 per cent decrease in energy consumption and is the first in New York State to achieve the demanding standard established by the Passive House Institute®, Germany.

Neopor® is featured in the first certified Passive House in New York State. Designed by Dennis Wedlick Architect, LLC (DWA). This three-bedroom home achieved a 90 per cent decrease in energy consumption and is the first in New York State to achieve the demanding standard established by the Passive House Institute®, Germany.

Neopor® is used in wall, roof and ceiling insulation in the zero heating cost house in Ludwigshafen, Germany so that the building incurs minimum heating costs.