The VFL 540 street light is one of WE-EF’s most sustainable products. Using far less material than other comparable products, it saves significant levels of energy, reduces the need for maintenance, and has a substantial recyclable value.

With a product lifetime of up to 20 years, or approximately 80,000 hours of operation, the VFL 540 can be disassembled into its component form. Its body is made of recycled aluminium and can be readily recycled again. At the same time, the LED boards and electronic components can be shredded, with the precious metals fully retrievable. The stainless steel fasteners can also be recycled.

Compared to conventional street lighting products, such as the 250w Metal Halide We-EF product, the VFL 540 is 96w or less, depending on the lighting task.

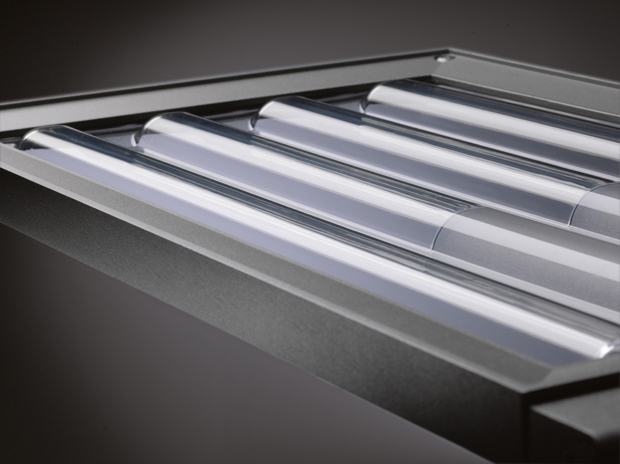

The lighting control and efficiencies for the product are enabled by the world leading OLC® & RFC® technologies. OLC® technology (multi-layer principle) is based on an array of LEDs being fitted with individual lenses that provide the identical distribution footprint. This means that in the event of a failure of an LED, the footprint might reduce in intensity, but not in terms of distribution.

The RFC® technology is another WE-EF innovation. The conventional flat glass panel or cover is replaced by a UV-stabilised acrylic panel which has a contoured surface. This substantially reduces the phenomenon of ‘internal reflection’, allowing poles to be spaced up to 40 per cent further apart, which in turn, reduces the need for more materials.

Moreover, the VFL 540 is not expected to be re-lamped in its 20 year lifespan. This differs from the conventional Metal Halide lighting products which not only extensively utilise resources such as iron and copper, but also require the lamp to be replaced every four to six years.

RoHS compliant, this product delivers great performance and exceptional energy benefits. The completion of a two year LCA project has led to the release of the industry’s first EPD – Environmental Product Declaration, which means that any client, purchaser or user can be confident of the VFL 540’s environmental credentials.

INITIATIVES

-

Physical size of all components including the product itself has been reduced, thus also reducing the demand for materials and resources

-

The LED boards and electronic control units are easily removable to ‘future-proof’ the product, permitting upgrades to new innovations in what is a fast moving technological environment

-

Product can be made even more efficient by the use of ‘smart controls’ such as motion detection, whereby little or no energy is being consumed unless there is activity in the space concerned

-

Early production of WE-EF LED streetlights was based on the use of virgin aluminium. Today the VFL 540, as well as the complete range, is produced solely from recycled marine grade material. Recycled aluminium is produced with just 5% of the energy required to produce virgin aluminium

-

Over 90% of the product is recyclable at end of life

-

It is accredited by the Dark Sky Association, and meets the requirements of AS/NZS 60598.1